SHARE

SHARE

Warehouse Management in Chaos? Let's Get to Know the WMS System

Sovia

Warehouses are a crucial part of the supply chain across various industries, from manufacturing and distribution to retail businesses.

Their role goes beyond just storage; they also function as transit hubs that ensure the smooth flow of goods.

That’s why efficient warehouse management is key to supporting seamless business operations as a whole.

One widely adopted solution is the Warehouse Management System (WMS). This system helps streamline the inbound and outbound flow of goods, making it more organized, faster, and controlled.

WMS is no longer limited to factories or distribution centers, it is now being used in restaurants and food businesses too. The goal remains the same, to maintain stock levels and ensure smooth operations.

Let’s dive deeper into how WMS works in this article!

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a system specifically designed to manage all warehouse activities. It covers the processes of receiving, storing, and shipping goods from the warehouse. The main goal is to ensure that goods move efficiently, cost-effectively, and in an orderly manner.

WMS is a critical component of supply chain management that supports logistics efficiency. With this technology, every item in the warehouse can be tracked and managed in real time, leading to more accurate and productive warehouse operations.

WMS is a flexible digital solution that can be tailored to a business's needs. It can function as a standalone system or be integrated with other systems like Enterprise Resource Planning (ERP). This makes it ideal for businesses of various types and scales.

In practice, WMS is not only used in large distribution centers. Some restaurants have started using WMS to manage raw material inventory, ensuring ingredients are available when needed without overstocking.

Overall, WMS helps businesses maintain stock availability in a neat and efficient way. Implementing this system can be a strategic move to accelerate operations and improve customer satisfaction.

Read more: Unraveling What Data Warehouse is: Its Functions and Characteristics

Understanding the Concept of WMS

Source: freepik.com

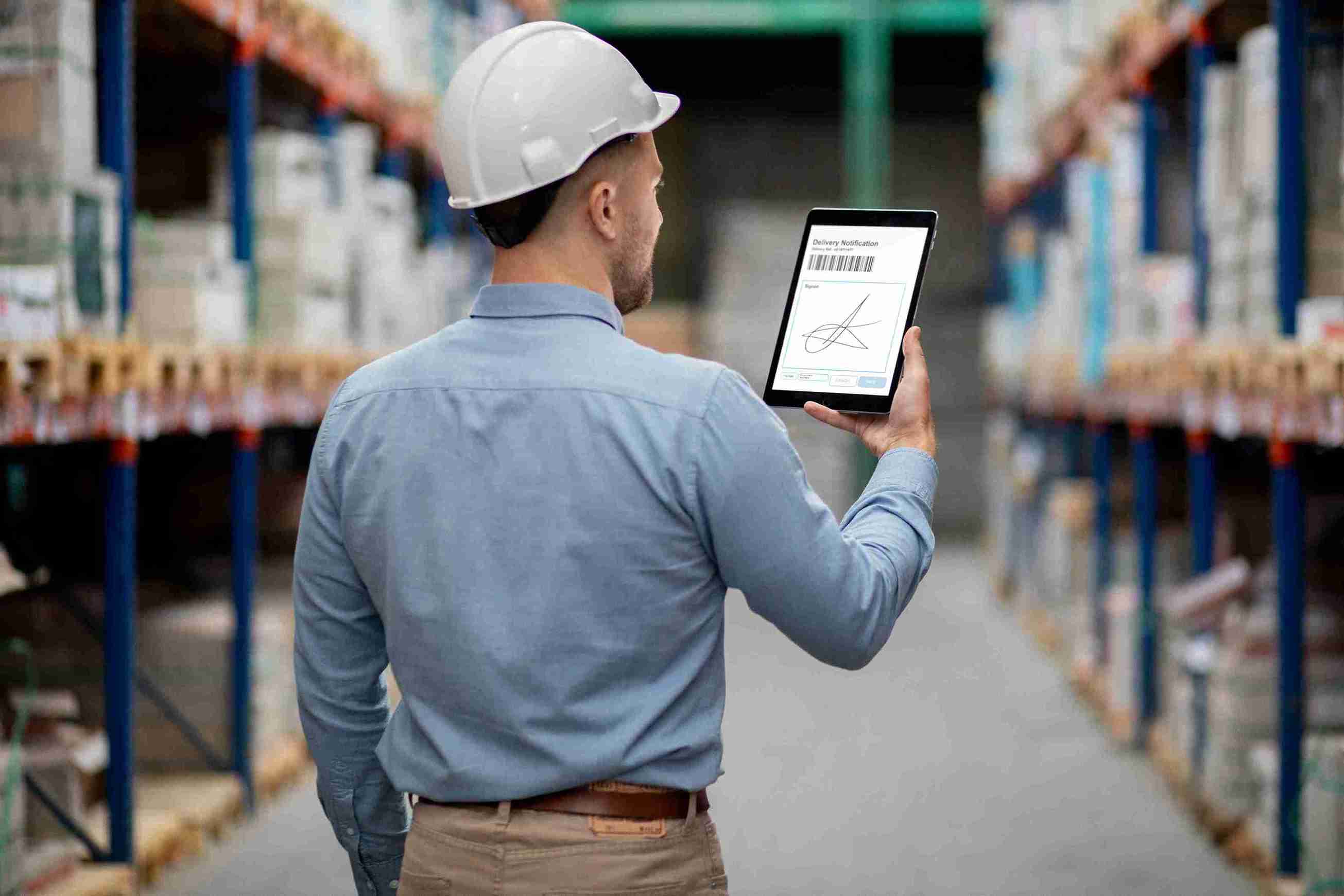

A Warehouse Management System (WMS) helps regulate the flow of goods in and out of the warehouse efficiently.

One of the key concepts in WMS is FIFO (First In, First Out), which ensures that older stock is used or shipped before newer stock. This method is especially useful for perishable products like food and raw ingredients.

Another concept is LIFO (Last In, First Out), where the most recently received goods are used or shipped first. This is often applied to items like sand or building materials that are stacked in layers.

There's also FEFO (First Expired, First Out), which prioritizes goods closest to their expiration date. FEFO is commonly used in food, beverage, and pharmaceutical industries to maintain product quality.

WMS applications allow each product to be assigned a unique identifier through barcodes. These barcodes are used to automatically record storage locations and item movements, minimizing data entry errors and speeding up the search process within the warehouse.

WMS isn't limited to large industries, it also benefits restaurant businesses. With WMS, restaurants can manage their raw material inventory more accurately and quickly, ensuring fresh ingredients are used first to maintain food quality.

Read more: First In First Out: A Stock Management Method to Reduce Waste in the Food Business

Benefits of Implementing a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a smart solution for more efficient, accurate, and organized warehouse management. Its implementation has proven to improve operational efficiency and reduce potential losses by up to 90%.

It’s suitable for all types of businesses, including restaurants that need to manage their ingredients precisely. Here are the key benefits of using a WMS:

1. More Efficient Warehouse Processes

WMS automates processes such as sorting, recording, and packaging. Manual workflows are replaced with faster and more accurate systems, especially helpful in handling large volumes of goods, such as fresh ingredients with short shelf lives in restaurants.

2. Better Organized Storage

WMS optimizes storage layout management. Items can be placed according to a systematic warehouse layout, making them easier to locate.

It also supports FIFO implementation to maintain product quality and reduce the risk of spoilage or expired goods, particularly for food and beverages.

3. Streamlined Warehouse Workflow

WMS provides notifications for incoming goods and facilitates faster receiving and storage. With pre-defined storage locations in the system, retrieval and sorting processes become much more efficient.

4. Improved Inventory and Shipping Accuracy

Inventory errors are minimized as WMS automatically and accurately updates stock data. Picking, packing, and shipping processes become faster and more precise.

Technologies like RFID or barcodes help track items, ensuring timely and accurate deliveries.

5. Integrated Inbound Stock Management

Inbound stock requests are aligned with current inventory data in the system, preventing overstock and reducing the buildup of aged inventory.

Each item is immediately labeled and recorded, allowing for clear traceability, especially important in restaurant kitchens where daily ingredient needs must be met precisely.

6. More Organized Outbound Process

When there is a delivery request, WMS matches it with actual stock data. Delivery schedules can be automated, making outbound processes more efficient and timely.

This is essential to maintain customer trust and ensure a consistent distribution rhythm.

7. Better-Controlled Operational Costs

Though it may seem complex, many cloud-based WMS solutions are cost-effective, requiring no additional hardware. With accurate automation, losses due to misplaced or damaged stock can be minimized, and operational time can be significantly reduced.

Conclusion

The Warehouse Management System (WMS) is the answer to more efficient and controlled warehouse operations.

It enables faster and more accurate processes, going beyond stock recording to real-time organization and movement of goods.

Automate your restaurant operations with ESB Core, a modern ERP system that helps streamline business processes, including inventory management, cost of goods sold (COGS), and comprehensive financial reporting, from balance sheets to profit & loss and cash flow management.

Manage all your branches in one integrated system and monitor business performance in real time, anytime, anywhere. Contact the ESB team today and start optimizing your business!

SHARE

SHARE